Global supply chains are under pressure from many directions, not least of which is the critical shortage of warehouse labor. Could more agile deployment of automation in the warehouse be part of the solution?

With Christmas just around the corner, a spotlight is being shone more strongly than ever before on the supply chain labor shortage. Predictably, grabbing the news headlines are warnings of shortages in food, drink and toys – but this global problem threatens to disrupt supply chains across all sectors. And with the peak events of Black Friday, Cyber Monday and the holiday season potentially combining with staff absence due to Covid-19, the challenges appear to be piling up.

As e-commerce continues its rapid upward trajectory, fuelled by the pandemic, it’s no surprise then that there is increasing interest being shown in the automation of supply chains, with an estimated $36 billion forecast to be invested in robotics and other technologies this year.

But the nature of the conversation has now changed as Dwight Klappich, VP of research at Gartner explains: “In the 1980s, the main reason for investing in automation was to reduce labor costs. Now for almost half the clients, their primary reason is labor availability.”

Oscar De Bok, CEO of DHL Supply Chain says that the message is clear – logistics workers have no need to be wary of automation such as robots: “We need these types of collaborative robotics to cope with the increase in activity required in the supply chain. Our workforce is still drastically increasing.”

So with the need for labor being most pressing during peak periods, might some businesses be reluctant to make big investments in automation that isn’t required all year round?

The solution for such organizations could lie in more use of flexible automation.

Robotics as a service

Richard Foster, Director of Digital Manufacturing at DHL Supply Chain, explains the concept behind flexible automation: “Previously when people spoke about automation in the supply chain, it was about fixed industrial automation, which typically has a six to twelve month lead time. It’s heavy Capex, but with a good payback at the end of it. However, that might be a five-year return on investment. Our thinking at DHL was that our customers often require more flexibility than that. We therefore developed our own robotics integration team internally, to explore the possibilities of flexible automation – technology such as robotic arms that we can lease into an operation for a few months during peak and then take out. So customers can bring in more automation as they get busier, but when they get quieter they can send it back. It’s almost like robotics as a service.”

The work that the robots undertake often include tasks that are essential, but mundane or physically demanding, such as palletizing.

With people in the warehouse now a precious resource, it means humans can be used to the best of their ability – using skills that cannot be replicated by machines – rather than to undertake work that automated technologies can do faster and with less of a health and safety risk.

Unloading containers onto pallets, for example, is traditionally a manually demanding task. However, the use of automation is now making it safer, simpler and faster with a lower risk of repetitive strain injuries for warehouse workers.

How, though, can robots help with more bespoke tasks such as packing a variety of different shapes and sizes into packages?

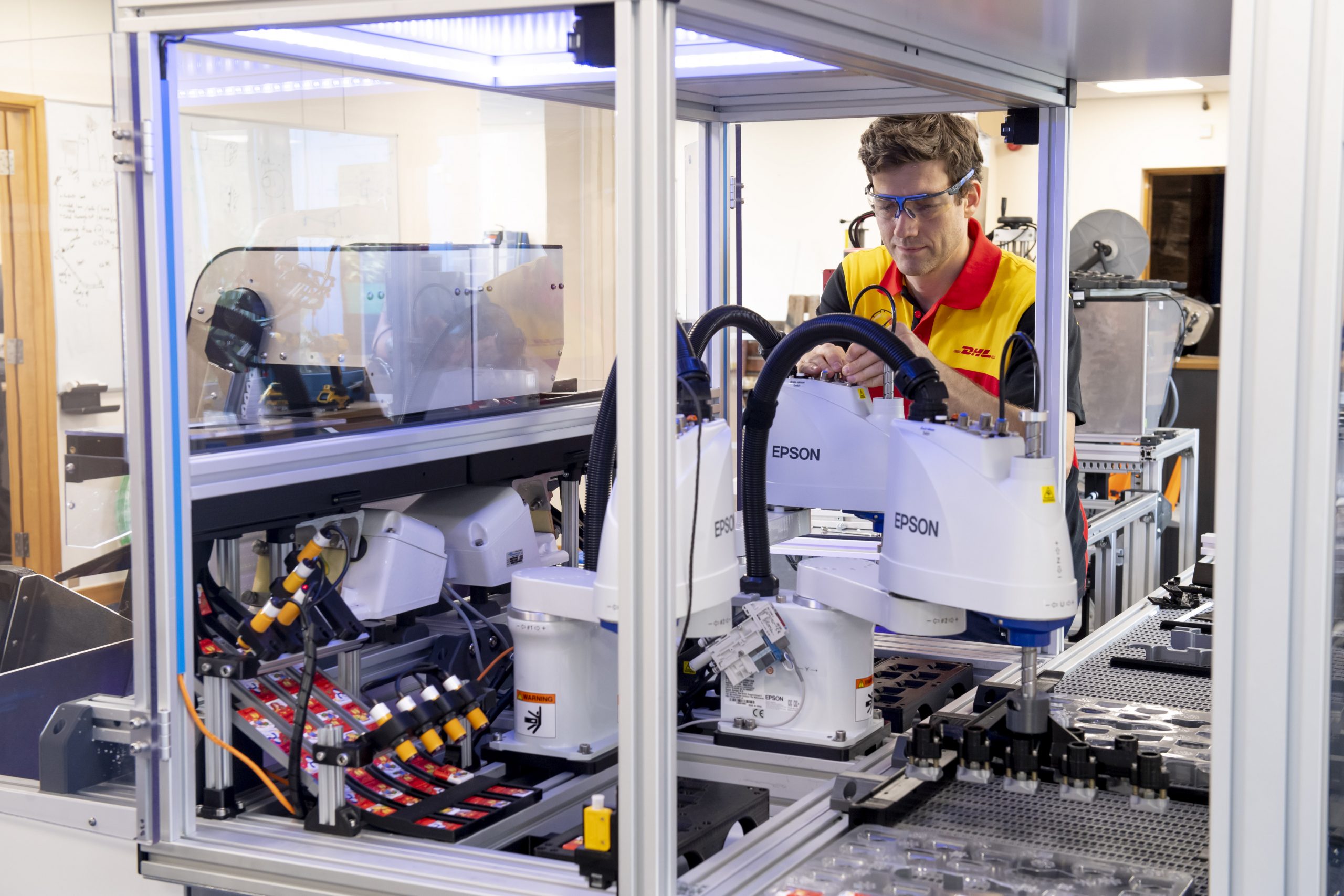

Richard points to the example of collaborative robots currently being used to fill advent calendars – a perfect example of a seasonal product – using 3-D printed grippers attached to robotic arms: “Previously, the calendars were all filled by hand, with each of the 24 differently shaped items being placed into the tray. It was an expensive and time-consuming way to do it, but the cost of automation was prohibitive to design it in a bespoke manner. However, advances in 3-D printing have allowed us to tailor the necessary parts quickly at relatively low cost so that robotic arms can take over the monotonous work previously carried out by humans.”

An opportunity to upskill

As well as making their jobs less mundane, and safer, there is another significant benefit for warehouse workers – the opportunity to learn new skills.

Rosie Heaps, VP HR – Retail & Consumer at DHL Supply Chain, says: “One of the reasons people often give for leaving a warehouse position is the lack of opportunity to learn and develop. Now, however, we’re giving people that opportunity to upskill. Having flexible automation in the warehouse is different to having a major industrial system in play that you might need an engineering qualification to maintain. Instead, flexible automation more commonly involves straightforward troubleshooting, which can be done by someone who has some experience of working with it.”

“We’ve moved away from a scenario where people sometimes felt almost threatened by technology to a point where they feel protected. We’ve taken away a lot of manually repetitive processes through the use of automation, and we’re training them not just in the things you would normally see in a warehouse such as forklift truck driving, but in engineering skills. We are looking for apprentices to be able to come and support our automation, and equally, with our managers, we’re having to train them to go beyond the core picking and packing activities that you would traditionally associate with a warehouse environment.”

“It’s why we’ve invested in our Supervisory Academy, which launched last year, and which equips our frontline colleagues with the skills to be able to manage change and implementations such as flexible automation. It also supports them with managing the changing nature of work.”

A win-win

With supply chain challenges showing no signs of abating any time soon, we are likely to see an increase in the use of flexible automation being deployed to tackle peaks.

At DHL Supply Chain we anticipate continuing demand for robot arms, with 3-D printing providing end-of-arm tooling, and also demand for support systems such as conveyors. These can be deployed for repetitive pick and place tasks that include palletizing loose-loaded products on receipt into a warehouse. The challenge here, says Richard, is to find cost-effective ways to apply these technologies to less uniform tasks, by adding in sensors, vision systems and machine learning to allow a broader range of deployments.

As these technologies become increasingly commonplace in the frontline, Rosie is confident that people will become even more comfortable working alongside automation. She says that, already, feedback from colleagues indicates that working alongside robotics and other automation is an enjoyable and interesting part of their role, which improves their job satisfaction.

“I think people used to perhaps have an attitude of ‘the robots are coming, they’re taking our jobs.’ But actually, they’re taking away the tasks that people don’t really want to do. They’re improving safety performance and taking on the largely repetitive tasks, such as shrink wrapping, which means we can train more of our colleagues to do the more value add activities.”

For DHL Supply Chain, that increase in employee satisfaction, combined with the flexibility and agility that our customers need, represents the perfect win-win.